Tensile and compressive stress and strain are two common types. Tensile stress increases an object's length, while compressive stress decreases it. These stresses help determine a material's elastic modulus, indicating its stiffness.

Tensile and compressive loads are key in mechanics and engineering. Tensile load stretches materials, causing elongation. Compressive load compresses materials, causing them to shorten.

Tensile Strength

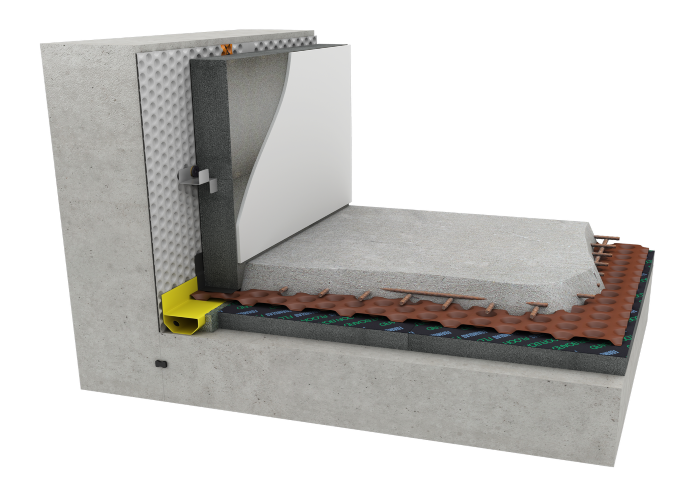

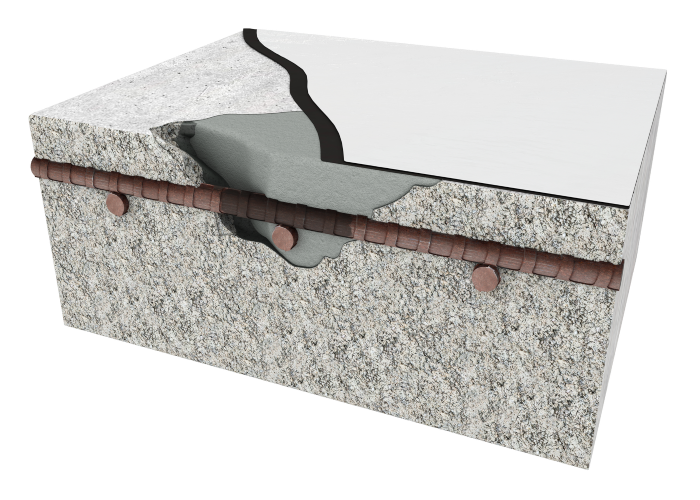

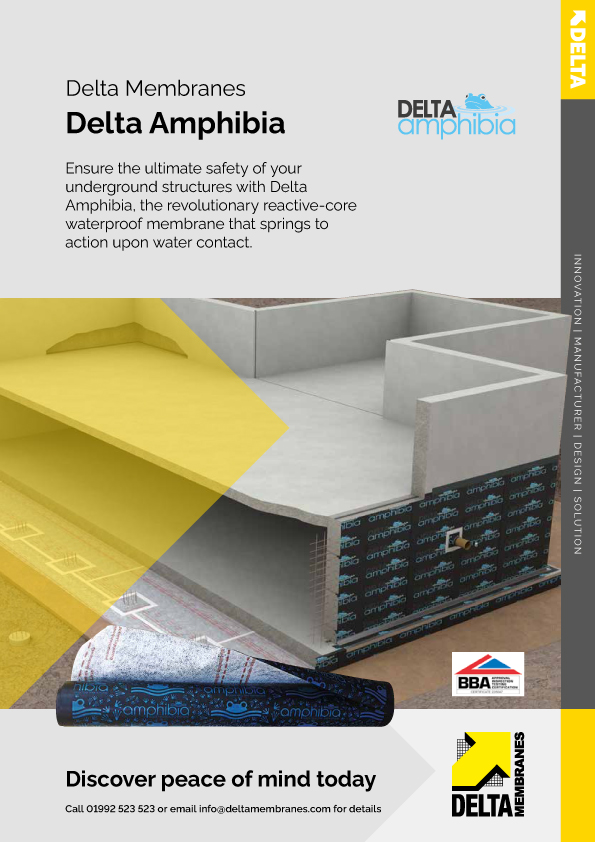

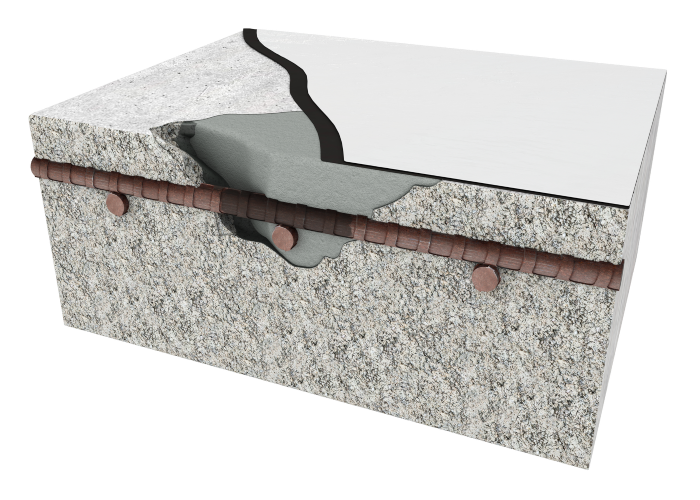

Tensile strength in structural waterproofing products is important to resist cracking and tearing under stress, preventing water penetration and ensuring a structure's longevity. High tensile strength is vital in areas prone to movement, where the waterproofing solution must withstand stretching and elongation without failing.

Tensile strength is measured by conducting a tensile test, also known as a tension or pull test, on a material sample. This test involves applying a gradually increasing tensile force to the sample until it breaks, while simultaneously measuring the force and deformation of the material. The maximum force the material withstands before breaking, divided by its original cross-sectional area, determines its tensile strength.

There are three types of tensile strength: Yield strength (A) is the stress a material can handle without permanent deformation. Ultimate strength (B) is the maximum stress it can endure. Breaking strength (C) is the stress level at the point of rupture.

A third-party tensile strength test evaluates a material's resistance to breaking under tension. Conducted by independent labs, it provides an unbiased assessment of mechanical properties. Results verify the material's suitability for high-stress applications.

Not all third-party construction product testing is the same. The goal is to ensure product performance and compliance, but standards, processes, and rigor vary between testing bodies.

It's important to follow manufacturer's instructions for safety, optimal performance, and longevity of products and equipment. This prevents accidents, injuries, and damage, while maximising efficiency and meeting warranty requirements.

Tensile strength is vital for crack bridging products as it measures the material's resistance to breaking under tension. It enables the material to span and seal cracks without fracturing. High tensile strength is essential to withstand the stress and strain from crack movement, preventing further damage and water ingress.

Compressive Strength

Tension is a force that pulls objects apart, while compression is a force that pushes objects together.

Compressive strength measures a material's ability to withstand forces that crush or squeeze it. It represents the maximum stress a material can endure before fracturing or deforming significantly under compression. Essentially, it gauges how well a material resists being pushed together.

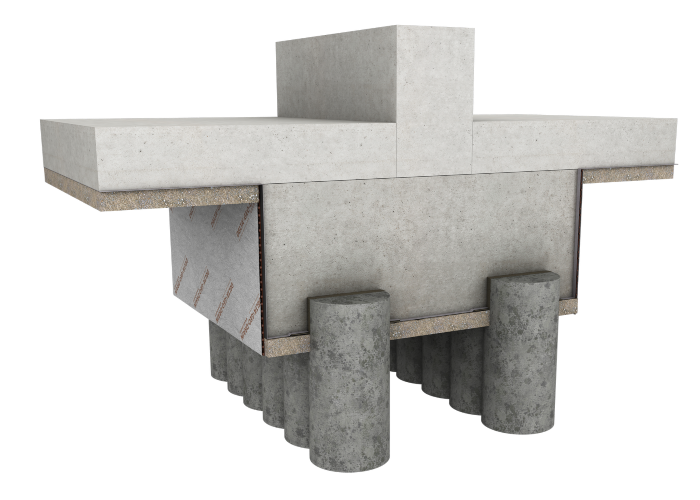

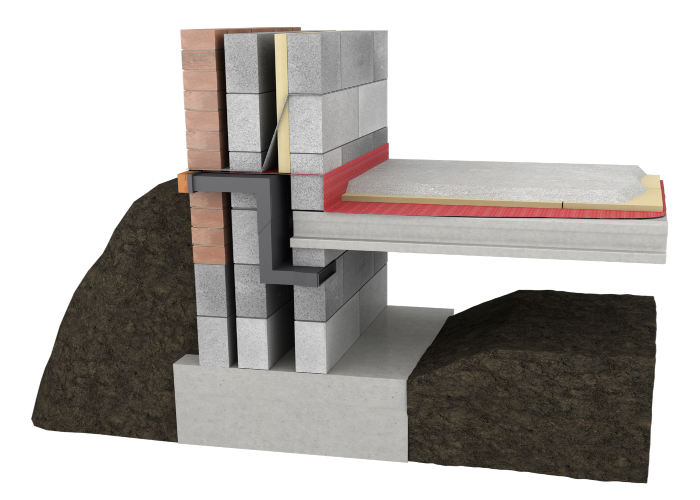

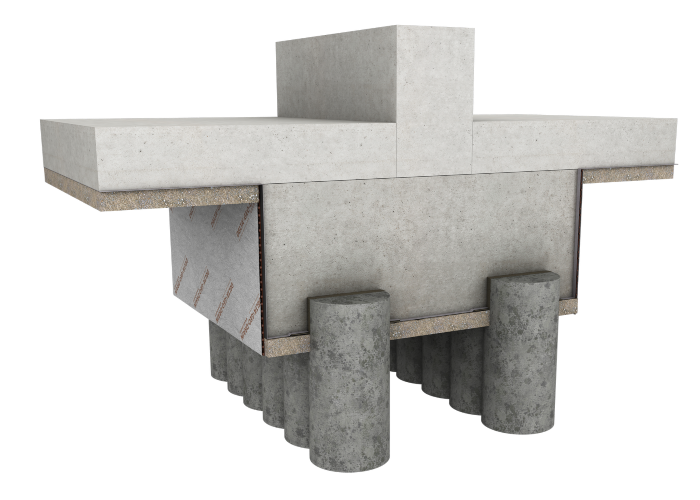

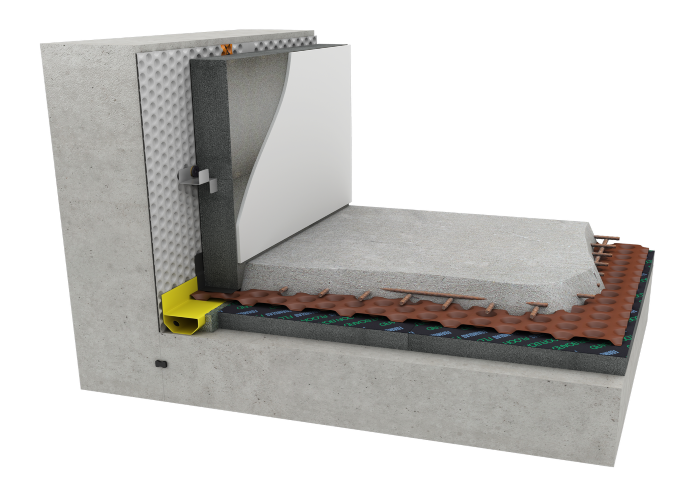

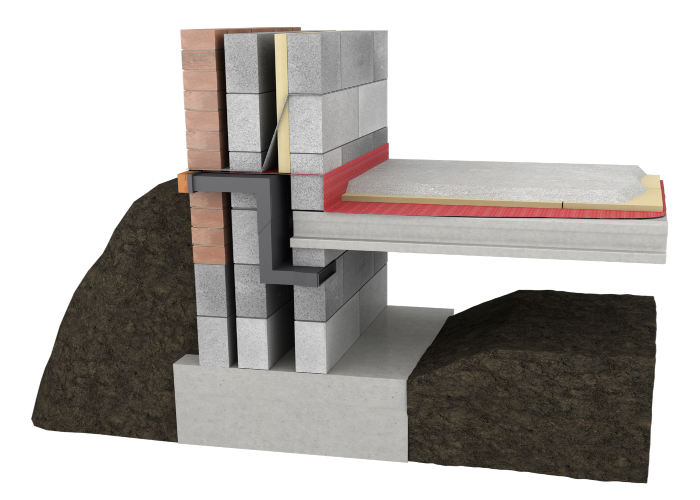

Compressive strength is vital for building materials, especially those supporting loads. It's essential in concrete foundations, columns, walls, bricks, masonry, and insulation used in floors and roofs.

Foundations transfer the weight of buildings into the ground. Concrete, often used for foundations, undergoes compressive strength tests to ensure it can bear the load.

Columns are vertical structural members, often made of reinforced concrete, that support beams and floors. Their compressive strength is crucial to prevent buckling under heavy loads.

Load-bearing walls must withstand forces from above. Bricks, concrete blocks, and some insulation types need enough compressive strength for this purpose.Floors and roofs must support the weight of people, furniture, and materials. Insulation in these areas needs strong compressive strength to avoid being crushed and losing its insulating properties.

Using materials with good compressive strength is vital for keeping a structure’s integrity.

Compressive strength of a membrane refers to its ability to withstand crushing or deformation under compressive force. It's a crucial mechanical property, especially for membranes used in construction, insulation, filtration and waterproofing applications, where they may be subjected to significant loads.

Always follow the manufacturer's guidelines for any construction or waterproofing product you use, regardless of general advice offered.

Manufacturer guidelines vary based on product types, materials, intended use, and regulations. These differences affect recommended installation, maintenance, and usage procedures due to each manufacturer's unique processes and standards.

Ask Questions

We encourage you to ask questions about our products and services. Transparency and honesty are our core values. Enquiring helps us learn, understand, and grow. It allows us to gather information, clarify doubts, and gain deeper insights. By asking questions, we engage in critical thinking and problem-solving, essential for personal and professional development. This fosters communication, collaboration, and open dialogue, leading to better decision-making and problem-solving.

Training

Manufacturer training is vital for implementing best practices, enhancing skills, and boosting career opportunities. It keeps you updated with industry trends and new technologies, making you more competitive. Training also improves job performance, productivity, and confidence, leading to higher job satisfaction and personal growth.

Always Happy to Help

Delta's office and field Technical Teams offer expert assistance to identify the ideal waterproofing system for your project, ensuring it meets your specific requirements precisely. For any inquiries about our products, we provide honest and accurate answers at all times.

Reach us at 01992 523 523 or drop us an email at info@deltamembranes.com.